Broader Implications of a Safety Culture

Safety in the manufacturing setup not only ensures an incident-free factory that avoids medical, legal, and rebuilding costs, but also makes plant personnel feel valued. This may be the reason why a 2017 survey discovered a rise in manufacturing productivity following execution of a safety program [1].

Dangerous Explosive Atmosphere (DEA) often results around a sugar grinding setup. At temperatures exceeding 1500C, sugar dust is inflammable when available in sufficiently high concentrations. This forms a Dangerous Explosive Atmosphere (DEA) which can be set off by an ignition source.

Among the most disastrous examples of sugar plant explosions is the 2008 blasts at the Imperial Sugar Refinery, Georgia. Sugar dust had accumulated at various locations in the factory. A single blast triggered a chain reaction of explosions and culminated in the death and injury of several people [2].

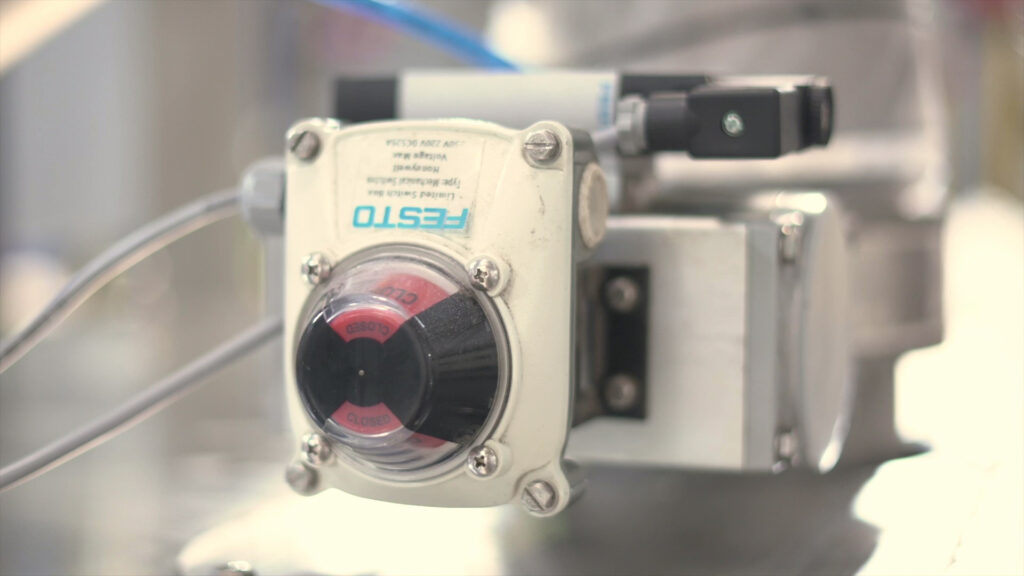

Compliance with Atmosphere Explosible (ATEX) guidelines ensures that the manufactured mechanical and electrical products (equipment, parts, and protective mechanisms) are explosion proof while operating in blast-prone conditions.

Sugar Grinding: Inherently Explosion Prone

A large part of energy used to grind sugar is dissipated as heat which raises the temperature. Sucrose decomposes into glucose and fructose above 1500C. Fructose then converts to hydroxymethylfurfural (HMF), which is flammable [3] and the reason behind sugar’s explosive nature.

Grinding breaks down sugar crystals into powder. The action multiplies the surface area and presents larger surface area for combustion. The mere presence of sugar powder is not a cause for concern. Explosion occurs when the following three conditions [4] occur at the same time [5]:

Talking of particle size, sugar dust is more explosive at smaller sizes because of the surface area magnification effect we noted. Sugar dust particles of:

Being an insulator, sugar dust prevents heat loss from hot surfaces when it settles on them. These hot surfaces are potential ignition sources. Major sources of sparks are:

Vulnerable Zones

Measures to prevent blasts focus on avoiding the formation of a DEA. Sometimes when preventive measures are not practical, constructional controls are put in place to restrict the impact of explosions.

Structural and organizational controls which respectively deal with the plant structure and company work culture can either be preventive or constructional in nature. The starting point is of course the identification of blast-prone zones.

Grinder apart, following equipment and / or locations in a sugar milling plant is / are exposed to sugar dust accumulation:

ATEX classifies the areas in sugar grinding where DEA is formed frequently, constantly, or for longer durations as Zone 20. These are [5]:

Finally

In theory, ATEX directives apply to the equipment and devices located inside the blast-exposed zone. But since the overall objective is explosion prevention-control, they should also apply to equipment and devices placed outside the said zone.

Extending the same logic, organizational controls form the backbone of safety measures because they make safety a part of the work culture, a culture that ensures the vibrant functioning of the other controls – preventive, constructional, and structural as we shall see in the next article.

Cybernetik adheres to the highest standards of safety for Sugar Grinding Solutions. Our focus on safety begins at the design stage wherein we build safeguards into our solutions. And, we continue with this approach across the manufacturing, testing, and deployment stages.

References