Global populations are surging [1] and so are the number of people entering the workforce, worldwide spending on food, and disposable incomes [2]. Nuclear families with two working members have little time for cooking [3]. Globalization has made western lifestyles and exotic cuisines more acceptable [1].

While these factors close ranks to fuel the demand for convenience foods, expanding production takes time. For safety standards in the food industry are steep [4], margins are wafer thin [5], and recalls are the worst profitability killers [6]. Plus, food manufacturing is viable only with mass production.

Automation helps achieve the twin objectives of mass production-packaging while maintaining stringent hygiene standards. Traditionally labour intensive, the industry adopted automation with delay partly because of the inherent variations in raw material shape, size, and quality aspects [7].

But the need to automate always existed with most manual operations in the food industry being repetitive, fast, and monotonous. This led to deficient quality control, low motivation, and high occurrence of accidents, which escalated expenses [7].

Convenience foods (Ready to Eat [RTE] and Ready to Heat / Cook [RTH/C]) have been popular in the developed world for long [8]. Their inroads in the emerging markets such as India is recent. Statista expects the global convenience foods industry at $588.9 billion in 2022 to expand at 5.64% till 2026 [9].

Packaging is crucial for convenience foods that need to be edible across their shelf lives. RTE packaging relies on retort pouches made of composite material that don’t require brine addition. RTH/C foods use packaging materials based on specific requirements [10].

Excessive convenience food intake may prove bad for health [8]. Plus, they are more expensive than freshly prepared meals [11]. In the near future, this will further expand the use of natural and organic ingredients [12].

The future

of automation is here.

Statista places the 2022 revenues for the global convenience food market at $588.9 billion [9]. Data Bridge forecasts the same for the convenience and frozen food market at $344.76 billion by 2029 [13]. Here are the market drivers:

Here is what makes convenience foods convenient:

On the downside, convenient foods:

Related to these limitations are the roadblocks in their growth:

As we move ahead, convenience foods will include more natural and organic ingredients. Manufacturers will also try to limit the amount of mentioned ingredients that prove detrimental when consumed in large quantities.

Also called tertiary foods, convenience foods are processed foodstuffs that are easy to acquire, consume, and clean-up. This definition excludes raw edible fruits and vegetables. Based on whether they need to be prepared before consuming:

RTE and RTH/C foods can both be either frozen or shelf stable, which is another way to classify them.

Popular convenience preparations in India include [2]:

Packaging is crucial for RTE/H foods to be edible over their shelf lives. Microbes, food chemical interactions that attract microbes, and physical damage due to improper storage and handling are the major causes of food spoilage [15]. Dehydration, refrigeration-freezing, and canning are the three counter methods generally employed [16].

Material and procedures for packaging depend on [10]:

| Composite Material | Features | Applications | ||||||||||||

| Foil (9 mm) – Adhesive – Paper – Composite Micro Wax – Tissue (20 gm per m2) | Low water vapour transmission rate (WVTR) | Biscuit overwrap | ||||||||||||

| Foil (9 mm) – Adhesive – Paper – Extruded Polyethylene | – Blocks moisture – Machine friendly | Soup etc. packing in fin sealed sachets or pouches | ||||||||||||

| Foil (9 mm) – Adhesive – Paper with Heat Blocking Vinyl Resin Coating | – Blocks moisture – Machine friendly | Confectionary overwrap | ||||||||||||

| Polyethylene (1 inch) – Foil (9 mm) – Adhesive – Paper | Heat seals as wax bleeds via tissue | Confectionary overwrap | ||||||||||||

| Foil | – Machine friendly – Good WVTR | – Confectionary overwrap – Biscuit overwrap | ||||||||||||

| Cellophane layer – Adhesive layer – Pliofilm layer | – Transparent – Blocks gas | Nuts in inert gas packages | ||||||||||||

| Cellophane layer – Wad layer – Cellophane layer | – Sandwich printing – Good WVTR – Machine friendly | Hygroscopic material in pouches / bags | ||||||||||||

| Cellophane – Polyethylene | – Trapped printing – Blocks gas | Chocolates | ||||||||||||

| Polyester layer – Adhesive layer – Foil layer – Polyethylene layer | – Retains aroma – Blocks gas – Rigid – Heat resistant | Cans – process-able and flexible | ||||||||||||

| Polyester Film – Polyethylene (saran coated) | – Seals positively – High strength | Food pouches (vacuumed) |

Retort Processed RTE Foods: Such as rice, biryani, upma, dal fry, and palak paneer are retort processed [10] i.e. subjected to sterilizing heat treatment after packaging inside hermetically sealed, multilayer pouches [17]. Gas-flushing removes oxygen from the headspace of the pouch before packaging [10].

Also called Autoclaves or Sterilizers, retorts use steam or water to heat the pouches to between 1100C (2300F) and 1350C (2750F) [18] at high pressure and hold them there for up to 30 min [19]. Clostridium botulinum is a particularly notorious food poisoning microbe for it can withstand extreme heat [20].

Retort pouch material is:

Among the popular materials used for flat retort pouches in India is PET – Aluminium Foil – PP 3-ply Laminate with 12, 12, and 75 micron thickness of the respective materials. Stand up pouches use laminate with 12, 9, 15, and 60 microns respectively of PET, aluminium foil, OPA, and PP [10].

Other materials suited for retort pouches to store moisture-rich Indian foods include [10]:

Non Retort Processed RTE Foods: Idli, pizza, pav bhaji, and dosas are not retort processed on account of their extremely short shelf lives. Packaging material for these needs to [10]:

Materials used for packaging these foods are [10]:

RTC Foods have the following packaging requirements [10]:

RTC foods can also be classed based on their composition and moisture content:

| Sr. No. | RTC Food Type | Examples | Observations | Packaging Material | |||||||||||||||||||

| 1. | Cereal Based | Dosa, idli, chakli | – Contain 8-10% moisture. – Lose texture at 12-13% moisture. | Polyolefin pouches, 37-75 micron thick for 3-4 months shelf life. | |||||||||||||||||||

| 2. | Fat Heavy | Cakes, jamum, donuts | Turn rancid after reacting with water vapour and oxygen. | – CPP Pouches, 200 grams holding capacity for 2-3 month shelf life. – HD-LDPE or LDPE films for longer lives. | |||||||||||||||||||

| 3. | Pulses or Legume Rich | Khara sev, urad bath, vada, bonda | Packing material needs more moisture resistance than for cereal-based ones. | PP and LDPE impart shelf life of: – 5-6 months at normal ambiences. – 1.5-3 months at high relative humidity and temperatures. | |||||||||||||||||||

| 4. | Enriched Spice Mixes | Soups, rasam, bisibele bath, sambhar | – Polyamide-core-co-extruded films. – PET or PE that is either metallized or plain. – Cellophane / PE. | ||||||||||||||||||||

| 5. | Food Mixes | Tamarind sauce, orange peel gravy | Innermost packaging layer must: – Block moisture. – Not react with flavours and fats. | – Copolymer of acrylic acid and ethylene with a co-extruded HD-LDPE layer as the innermost sheet. | |||||||||||||||||||

| 6. | Low Moisture Items | Have: 1-5% moisture.18-20% Equilibrium Relative Humidity (ERH). | – Packaging material needs below 1 gm/m2/day Moisture Vapour Transmission Rate (MVTR) to prevent moisture in-flow. | ||||||||||||||||||||

| 7. | Medium Moisture Items | Sweetmeats, salty-spicy foods with: 6-20% moisture.65% max ERH. | – Shelf life is more important than MVTR as these are prone to microbial spoilage. | ||||||||||||||||||||

| 8. | High Moisture Items | Sauces, cakes, breads, chutneys, pickles, chappatis with: – 20-60% humidity. – 85% ERH. | Vulnerable to: – Microbial spoilage. – Yeast or mould formations due to condensed moisture. | For: – Long shelf life: Retort pouches, cans, or aseptic packs after sterilization. – Short shelf life: LDPE that allows moisture to diffuse out. |

Being compatible with machines is an important criteria for packaging material because robotic automation is increasingly employed for food packaging. Robots provide flexibility and are compatible with repetitive operations over a range of loads at greater productivity, food safety, and uptime.

Hygiene is invariably the first. Retaining nutritional value, aroma, and texture are not far behind. Convenience foods become convenient only with a reasonably long shelf life. Then again, the setup has to be safe for factory floor operatives. A system that uses minimal energy and time makes good returns.

Desirable features of an industrial cooking system are:

Automation is an excellent way to fulfil all these necessities.

Proper equipment, skilled workforce, exacting quality control measures, and correct management practices are necessary to operate successfully in the food industry where stringent regulatory standards, low margins, tight competition, and seasonal demand spikes are the norm. Modifications in product lines are not infrequent [5].

Food industry has traditionally been labour intensive with repetitive, fast, and monotonous operations lowering quality control, motivation, safety, and profits. Following factors make it tough to automate the food industry [7]:

Here is what automation enables for the food industry:

Standardization and flexibility are at the diametrically opposite ends. And yet, automation helps food product makers achieve both!

Cybernetik’s Ready to Eat / Heat (RTE/H) System

Cybernetik’s RTE/H system delivers rapid cooking with nutrient and flavour retention. In view of the peculiar requirements of Indian cuisine, one device of the system can impart tadka. Recipe selection facilitates the preparation of multiple items.

Highlights:

Safety & Hygiene:

Standard RTE/H Solution

Cybernetik’s standard RTE/H solution is optimized for quality and productivity through the integration of pouch packing, retort treatment, and secondary and tertiary packaging with the industrial cooking system. The entire system – from loading raw materials in the Buggy to final packaging – requires minimal manual inputs.

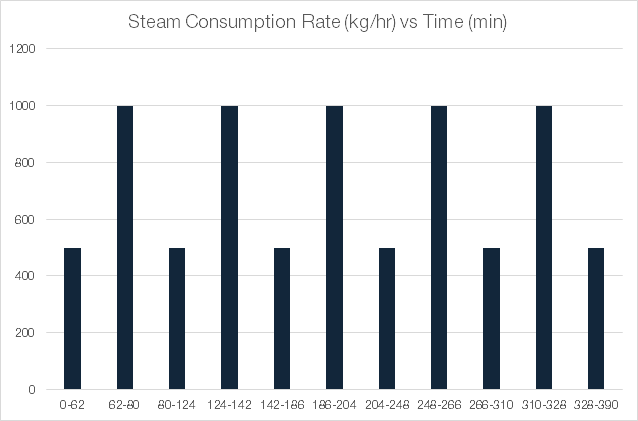

Plot 1: Steam Consumption (kg/hr) by the RTE/H System during a Shift

Cooking Kettles operate alternately with some overlap when both operate simultaneously. CIP System selectively rinses one Cooking Kettle while the other is operational to minimize downtime. If the system is delivering the same product, it is not necessary to rinse the Buffer Tank between batches.

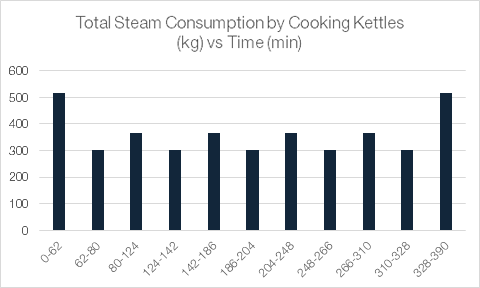

Plot 2: Total Steam Consumption (kg) during a Shift

Steam consumption rate is 500 kg/hr when one kettle is active and doubles to 1000 kg/hr when both operate. Total steam consumption during various durations in the shift is as shown in plot 2.

Finally

Growing populations and more importantly working populations will continue to drive the convenience foods market. Health concerns can limit this growth but producers are already moving towards natural and organic ingredients to address this. Automation will remain the best method to mass produce processed foods in compliance with the stringent standards of the industry.

Cybernetik delivers customized RTE/H solutions for hygienic, productive, and efficient production that use minimal water for cleaning. Write to us at [email protected] to know more on how we can automate your food production and processing plant.

References