Utility Unlimited

On 13 April 1970, an oxygen tank on board the Apollo-13 spacecraft exploded, seriously jeopardizing the lives of three astronauts. NASA mission controllers tinkered with the 15 training simulators and, despite the zero margin for error, quickly came up with fool-proof procedures that brought back all three astronauts safely to earth [1].

Although the term “digital twin” was not in use back then, this was perhaps its first application. That’s just about how useful even rudimentary digital twins were half a century ago. “Rudimentary” because simulators are not digital twins by themselves. The tinkering to replicate conditions in space brought them close to digital twins [1].

Cutting across to the present, Deloitte utilized digital twins to cut by 20% the changeover time for their manufacturing customers [2]. Boeing improved first-time part quality by 40% using digital twins [2]. GE’s digital wind farm promises to hike electricity generation by up to 20% enabling a single wind turbine to create $100 million more across its lifetime [3].

Digital twins first caught the mainstream in 2017 when technology consulting-research firm Gartner, Inc. named it as among the top ten trends for strategic technology. The firm repeated a similar rating in 2018 [4]. This explains why the global market for digital twins is predicted to jump from $3.1 billion in 2020 to $48.2 billion by 2026 [5].

What are Digital Twins?

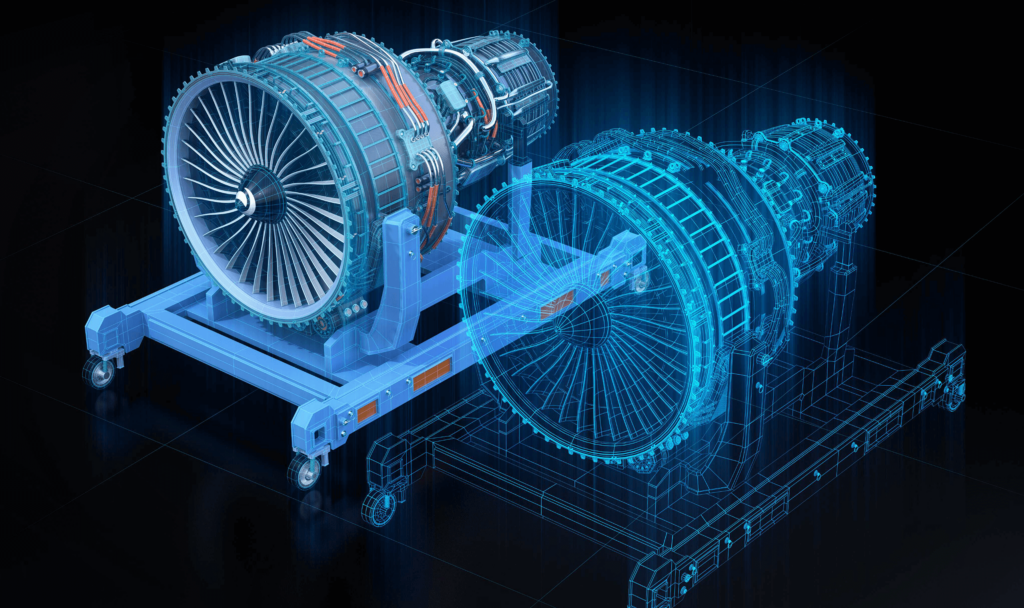

Digital twin is a virtual or digital model / representation / copy of a physical asset. The twin [5]:

Asset can be a product, a system, or a process. More specifically, the asset can be a manufacturing process, car, airplane, cargo ship, turbine, engine, city, bridge, building, offshore oil platform, or a human being, among other things.

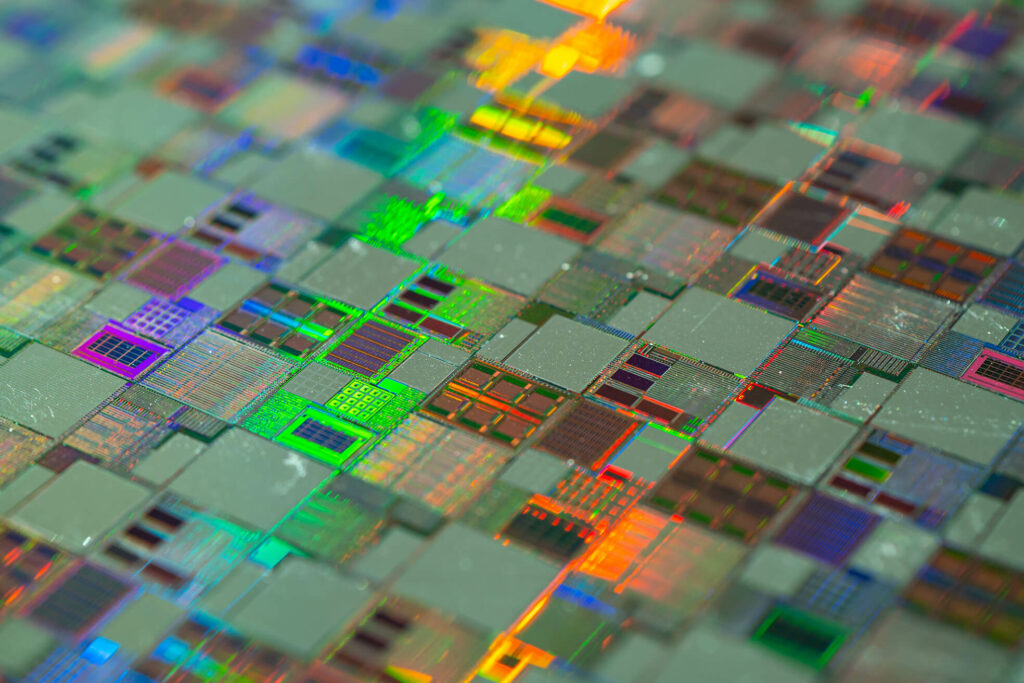

In short, digital twins are computer programs relying on real world data inputs to forecast asset performance [6]. Internet of Things (IoT) sensors capture this data that is also utilized to predict failure [4] and other problems.

Digital twin could also be based on a physical prototype of the asset, made to refine the performance of the full-scale asset before it is built. Alternatively, the twin itself can serve as the prototype [4].

Unlike simulations, digital twins study multiple processes and receive real time data. This empowers them to run numerous simulations to analyse multiple issues from a number of perspectives [5]. Predictive twins use recorded data from other physical assets [4] as opposed to real time data.

Except component and part twins, others handle data of multiple entities that operate together. Digital twin classification is based on the level they represent [5]:

Pros, Cons & Applications

With assets getting more complex, the need for intricate systems to develop, utilize, and maintain them is crucial. Customer expectations too are evolving rapidly and it makes sense to know these beforehand [7].

Advantages are related to the data they collect and evaluate. Digital twins:

Digital twins are already in use for the following:

Not all assets merit the application of digital twins. As Gartner warns, they could sometimes be a technology overkill. Plus, they open up concerns related to cost, privacy, security, and integration [4].

Considering the involved complexities and costs, digital twins become viable only for large and complex products, processes, and systems such as [5]:

Digital Twins in Cybernetik

It is a standard practice in Cybernetik to use digital twin to check system performance before actual manufacturing followed by design modifications, if necessary. The objective is to:

To attain these goals, we employ a rigorous, tried and tested procedure that starts with the creation of a 3D model. This is then uploaded into process simulator software to generate a virtual model. Linking sensor inputs and PLC software to the virtual model gives a digital model. This model is then run at real time parameter values to test its performance. Gathered feedback serves to improve performance.

Finally

Health and capabilities of assets and the performance parameters of processes are critical for all and particularly asset-intensive sectors. With analytical capacity of digital twins expanding as a result of greater resource allocation to improve their cognitive abilities, their role in manufacturing will deepen further [5].

Cybernetik is a 30+ year old company that uses innovative automation to solve challenges of throughput, efficiency, hygiene, and safety. Write to us at [email protected] to know more on how we can be of assistance.

References