Sugar grinding and manual packing solution safely handles sugar milling, storage, and packaging at 1200 kg/hr. Considering that sugar is explosive at and above 150 deg-C, safety was the foremost parameter. Therefore, ATEX area was clearly demarcated.

Food

5 months

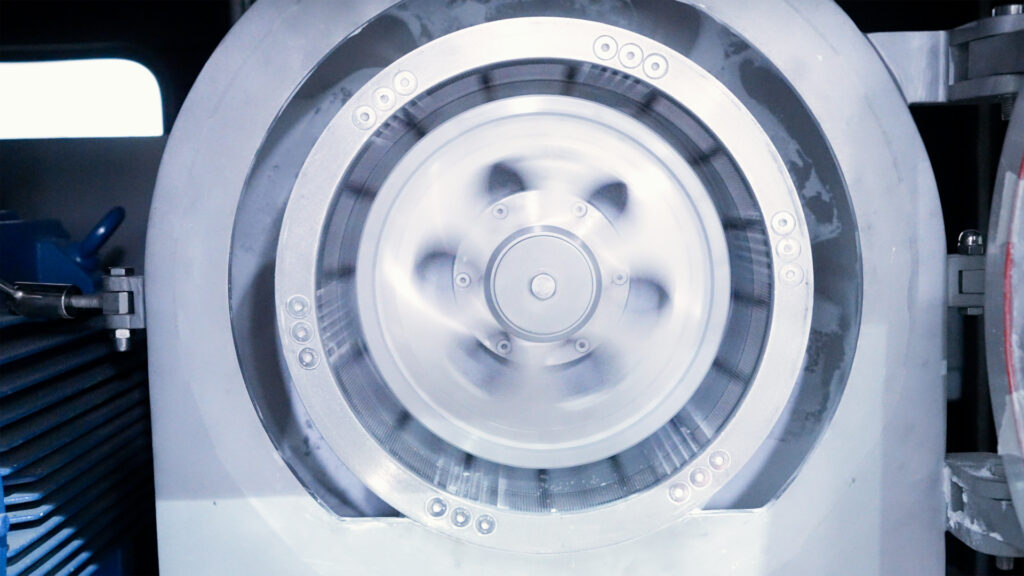

Available in four variants, Cybernetik Technologies’ sugar grinding plant is an integrated set up consisting of the following major equipment:

Cybernetik’s Sugar Grinding Solutions strike a balance between quality, productivity, and safety. Available in four variants from 400 to 2000 kg/hr, the system is an integrated set up consisting of the following major equipment:

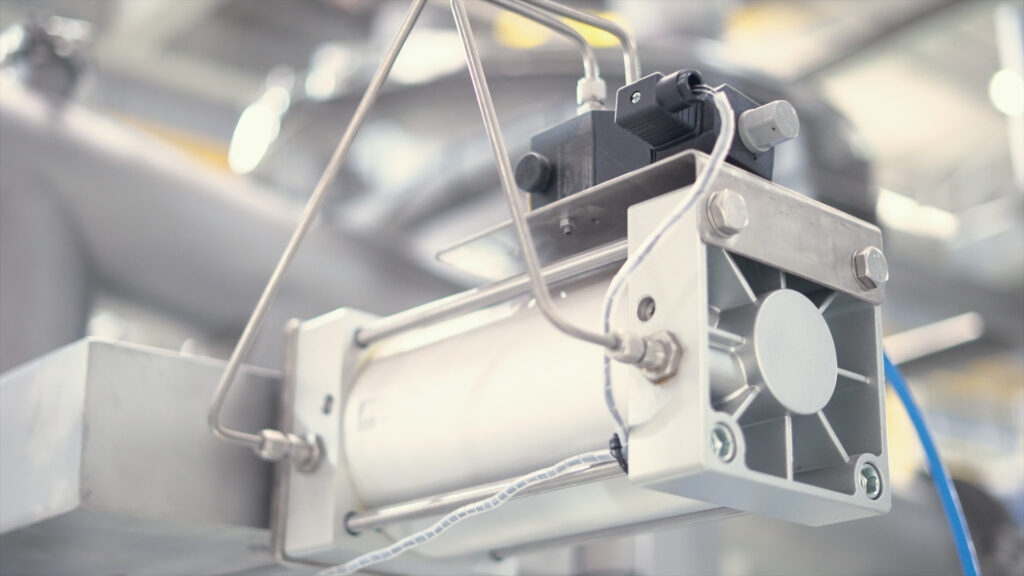

Designed with total satisfaction of the end-user as the guiding criteria, Cybernetik’s Sugar Grinding Solution comes with:

Safety features include:

Cybernetik offers advanced sugar-grinding solutions designed to ensure precision and efficiency in your production processes.