We develop efficient customized solutions for your adhesives and bonding business

Drum & IBC Decanting System

Single platform solution for decantation from drums and IBCs. Flush system for Lance prevents cross contamination of additives. Similar system is available for flushing drums with base oil. Tilting System inclines the drum or IBC to decant maximum possible additive to minimize wastage.

Submerged Conveyor

Inline pasteurization and cooling with automated, temperature-based Conveyor speed control. Food-grade, modular PVC Conveyor enables hygienic ambience and easy maintenance. Thermal insulation maintains temperature. The connected Singling Conveyor transports individual packets. Inspection Door allows quick access.

C Type & Z Type Bucket Elevators

Dust-free and contamination-free transfer of hygroscopic material to 20 m height at up to 4000 kg/hr. Designed to keep material spillage, maintenance, and downtime to a minimum, the solution has ingrained safety features, and allows continuous visual inspection during operation.

Powder Conveying System

Leak-proof, vacuum conveying solution for up to 8 mm size powders maintains product integrity. Conveying powders at up to 3000 kg/hr with minimal temperature rise, the system’s dust-free operation maintains a hygienic ambience. Optional features include ATEX construction and CIP System.

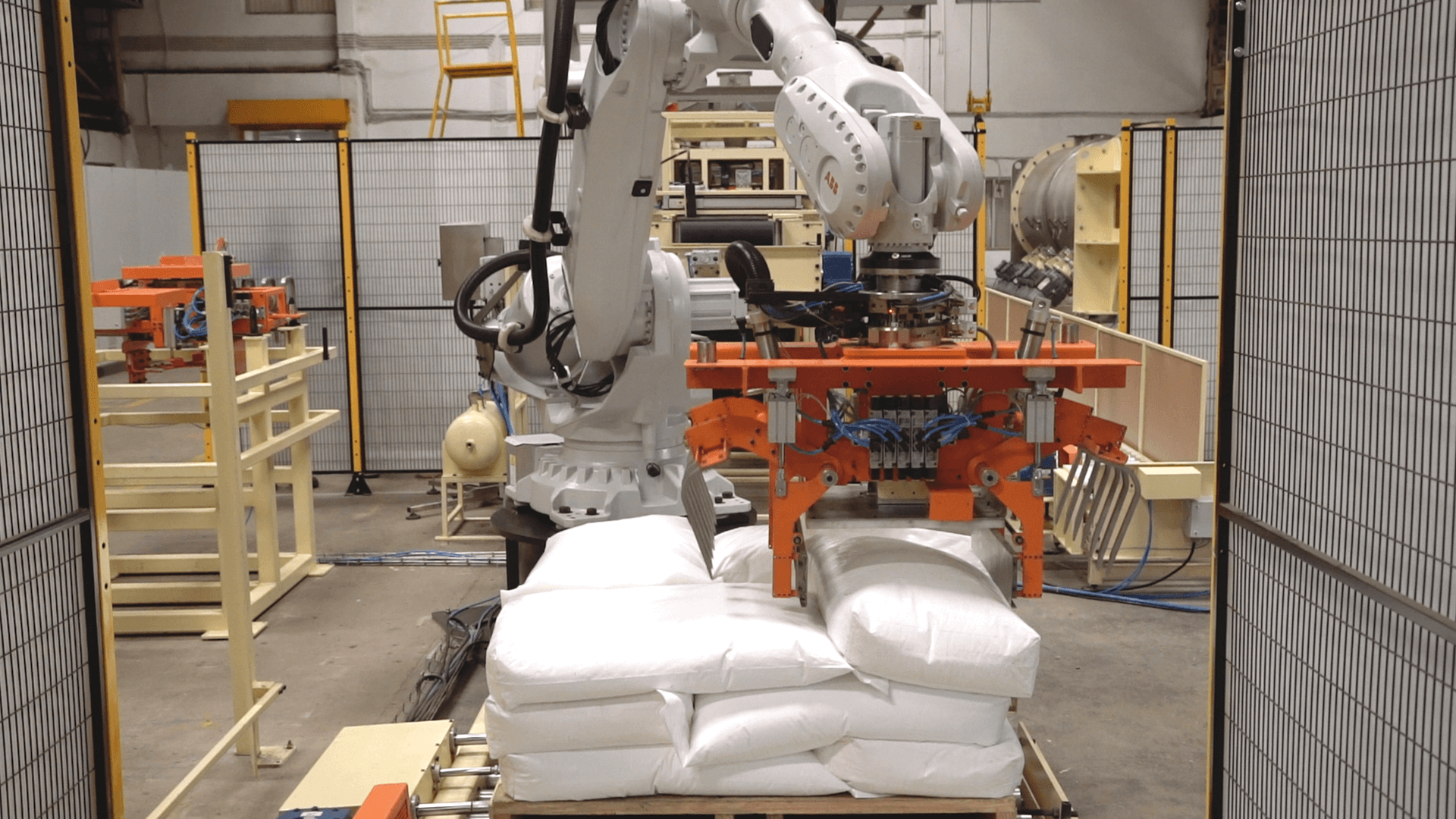

Bag Palletizer

Complete, end-of-line palletizing solution with operational integration.

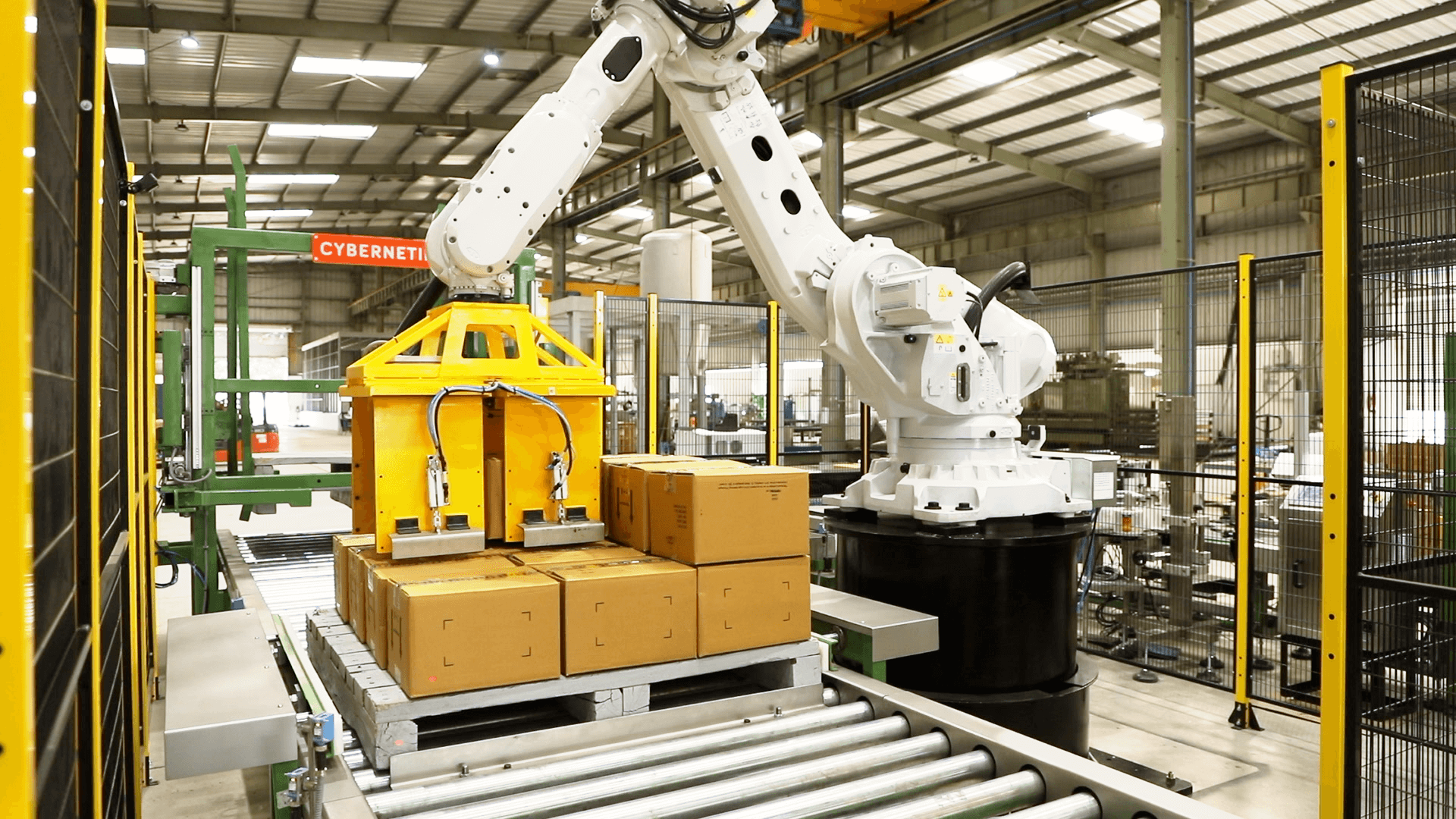

Box & Carton Palletizer

Customized palletizer for sturdy and handle-with-care boxes.

Drum & IBC Loading System

Fast, accurate, and safe solution for customized loading of drums and IBCs with liquids via recipe selection, Swing Arm positioning, Flow Meters, and Stoppers.

Drum Palletizer

Customized, safe palletizing solution for drums holding inflammable, hazardous, and stable liquids.

Pouch Conveying, Settling & Case Packing Automation

Integration of multiple operations for error free packing, metal detection, quality checks, and workforce reduction.

Integrated Pouch, Loose & Transpack Filling Automation

Integrated packing and palletizing solution for pouch packing, loose filling, and transpack filling with option to run 2 out of the 3 lines simultaneously.

"*" indicates required fields

Cybernetik is an industrial automation company that blends experience with innovation to design, build, and install end-to-end, customized automation solutions for the food, pharmaceutical, chemical, and manufacturing industries across the world.

Cybernetik was set up as a consultancy in 1989 by a group of engineers from the Indian Institute of Technology (IIT)-Madras, India and the State University of New York at Buffalo, USA.

From 10 people operating in less than 100 sq.m. workspace, our footprint in India has expanded to 30,000+ sq.m. across four units, two each in Pune, Maharashtra and Nadiad, Gujarat.

Our global operations are based out of three international offices:

Vietnam (for Southeast Asia), Dubai (for Middle East and Africa) and United States (for North America).